INFRA-RED THERMOGRAPHY (IRT)

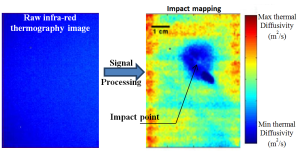

Infrared thermography is deployed by two approaches; passive and active. With the passive approach thermography is used to investigate materials that are at different temperature than ambient (often higher), whilst in the case of the active approach an external stimulus source (i.e. optical flash lamps, heat lamps, hot or cold air guns, etc.) is used in order to induce relevant thermal contrasts. The most regular applications of the passive approach in NDT are for buildings and infrastructures, maintenance, components and processes, and medicine. In most situations, passive thermography is used for qualitative assessment (although this is not always the case), given that the objective is to detect irregularities of the kind function or malfunction. The active approach has also several applications in NDT. The temperature differences during the transient phase appear on the material surface and so detection of subsurface defects is possible (areas of different temperatures when compared to the sound part(s) due to the different thermal diffusivity). Since the heating or cooling features of the stimulus source are identifiable by considering the time factor quantitative assessment is also feasible. The most common modes of active thermography are pulsed thermography, long pulsed heating or step heating transient thermography, optical lock-in thermography, and ultrasound lock-in thermography. The main advantage of infrared thermography over the destructive testing techniques is that large areas can be scanned fast and with no need to be destroyed during testing. This results in major savings in time, people, work and machinery. In addition, there are advantages of infrared thermography over the other non-destructive techniques. The infrared thermographic device is risk-free, as it does not emit any radiation; it only records the infrared radiation emitted from the material that is under assessment. Moreover, infrared thermography is an area investigating technique, whereas most of the other non-destructive methods are either point or line testing methods. Furthermore, infrared thermographic testing may be performed during both day – and night – time hours. Thermography, due to the fact that it uses infrared technology it is not possible to penetrate in extended depths (only a few mm’s). That of course is one of the main limitations of the technique. Finally, environmental conditions also play an important role on outdoor infrared thermographic surveys utilising the passive approach (i.e. cloud cover, solar radiation, wind speed).

Infrared thermography is deployed by two approaches; passive and active. With the passive approach thermography is used to investigate materials that are at different temperature than ambient (often higher), whilst in the case of the active approach an external stimulus source (i.e. optical flash lamps, heat lamps, hot or cold air guns, etc.) is used in order to induce relevant thermal contrasts. The most regular applications of the passive approach in NDT are for buildings and infrastructures, maintenance, components and processes, and medicine. In most situations, passive thermography is used for qualitative assessment (although this is not always the case), given that the objective is to detect irregularities of the kind function or malfunction. The active approach has also several applications in NDT. The temperature differences during the transient phase appear on the material surface and so detection of subsurface defects is possible (areas of different temperatures when compared to the sound part(s) due to the different thermal diffusivity). Since the heating or cooling features of the stimulus source are identifiable by considering the time factor quantitative assessment is also feasible. The most common modes of active thermography are pulsed thermography, long pulsed heating or step heating transient thermography, optical lock-in thermography, and ultrasound lock-in thermography. The main advantage of infrared thermography over the destructive testing techniques is that large areas can be scanned fast and with no need to be destroyed during testing. This results in major savings in time, people, work and machinery. In addition, there are advantages of infrared thermography over the other non-destructive techniques. The infrared thermographic device is risk-free, as it does not emit any radiation; it only records the infrared radiation emitted from the material that is under assessment. Moreover, infrared thermography is an area investigating technique, whereas most of the other non-destructive methods are either point or line testing methods. Furthermore, infrared thermographic testing may be performed during both day – and night – time hours. Thermography, due to the fact that it uses infrared technology it is not possible to penetrate in extended depths (only a few mm’s). That of course is one of the main limitations of the technique. Finally, environmental conditions also play an important role on outdoor infrared thermographic surveys utilising the passive approach (i.e. cloud cover, solar radiation, wind speed).

Olympus Omniscan MX

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more. To illustrate the general inspection principle, a typical pulse/echo inspection configuration as illustrated below will be used. A typical UT inspection system consists of several functional units, such as the pulser/receiver, transducer, and display devices. A pulser/receiver is an electronic device that can produce high voltage electrical pulses.

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more. To illustrate the general inspection principle, a typical pulse/echo inspection configuration as illustrated below will be used. A typical UT inspection system consists of several functional units, such as the pulser/receiver, transducer, and display devices. A pulser/receiver is an electronic device that can produce high voltage electrical pulses.