Robots for the nuclear industry

Robotics and AI 6th June 2022

Author: Thomas Johnson, The University of Manchester

All around the industrial world we are living through a robotic revolution. The nuclear industry is no exception to this. In fact, the inherent risk that radioactivity poses to humans has meant that robotics has been a part of the nuclear industry since the 1960s. We need robotics in order to move components in reactors, to complete our greatest decommissioning and dismantling challenges and to assess radioactivity in many areas to ensure the safety of operators and to reduce the costs of operations. Enabling operations to be cost-effective is increasingly important as nuclear power positions itself as a major part of our greener future for energy generation.

Robotics has played a part in the response to some of the nuclear industry’s most profound challenges. In the aftermath of the Chernobyl disaster, robotics was used to survey areas which were completely inaccessible to humans, as well as to assist the clean-up of some of the most radioactive environments. Robotics played a similar role in the response to the incidents at Three Mile Island and Fukushima. These early deployments of robotics provided a clear demonstration of the advantages to using robotics, as well as highlighting some of the challenges that are posed to robotics in radioactive areas.

The United Kingdom finds itself at the forefront of technological development in the nuclear industry, and as such, has driven much of the robotics development of the past decade. We have recently seen UAVs used to map radiation around Chernobyl, aquatic vehicles developed to survey previously inaccessible parts of the Fukushima Daiichi nuclear power plant and robots developed to perform many challenging characterisation tasks at Dounreay. The growing number of deployments is an important step towards realising the benefits that robotics can provide for the nuclear industry.

The characterisation of facilities is of crucial importance throughout their whole lifecycle. It is important to inspect assets through construction and operation so that faults can be identified, and so that radiation can be mapped to ensure the safety of workers. After a facility’s operation life is complete, characterisation is the key to ensure that decommissioning plans can be streamlined to reduce the time and cost for them. Ultimately, accurate characterisation is required so that we do not have to consign waste with undue caution. Due to the large costs associated with sending extra waste for ILW or HLW storage, any waste that can be consigned out of the scope for ILW or HLW can lead to large cost savings.

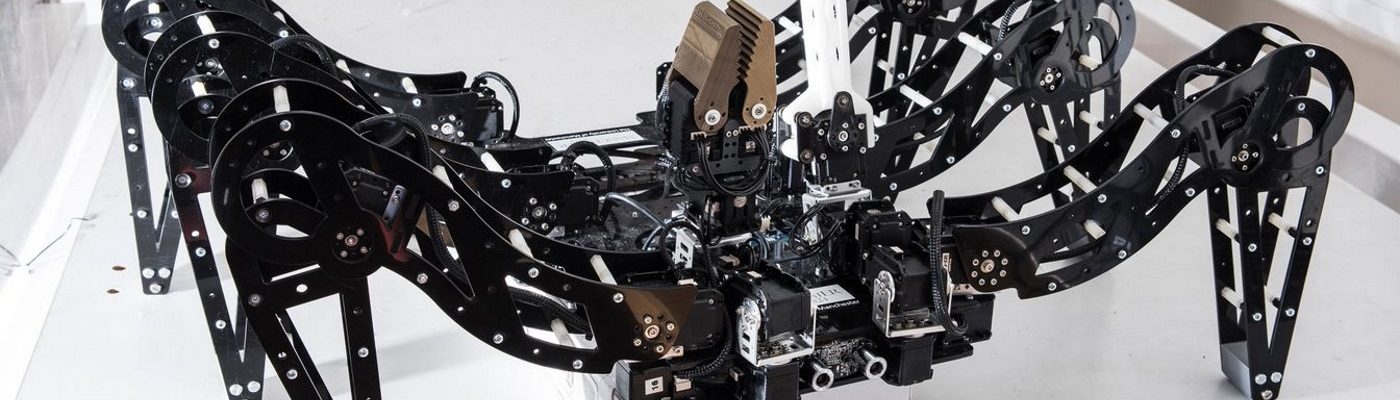

Robots are now used broadly in characterisation, to provide a large amount of physical, chemical and radiometric data. So where next? Although robotics is already a key part of operations in the nuclear industry, there remain a few barriers to more wide-scale use.

The first is due to the damage that radiation does to electronics. In areas where radiation is high, this can cause damage to electronic components. This has meant that past robots have had to use shielding, require redesigning or in some areas are not currently operational. The challenge of developing robots that are still highly functional and resistant to radiation is a complex one, but scientific R&D is pushing the frontiers of operation in this regard.

The second barrier is to develop robots that have the capability to help operations in more areas. The coming decade will see more development of robots which can help with the sorting and segregating of waste, as well as seeing robots which can help with the dismantling and decommissioning of facilities. As robotic capability is increased, we will see a decreased reliance on person ingress and this will provide great benefits in terms of safety, cost and time. The final barrier is one of technology adoption and acceptance. The nuclear industry is one which is very cautious, and so the adoption of new solutions can take a long time. With the growing number of deployments that we have seen through the past decade, and we will continue to see through the next, it feels as if robotics for nuclear has reached a critical mass, and we will see a greater willingness to adopt robotic solutions.