Waiter! There’s a cricket in my printer

Departments Research impact and institutes UOM life 21st June 2017

Remember when a printer was just something that spurted out paper documents and emails and that you occasionally (okay, frequently) shouted at? Chances are this is still the extent of your relationship with your printer – but that could all soon change.

For instance, imagine using a printer to prepare your perfect snack. A delicate chocolate spiral perhaps, or a cookie that contains the exact number of calories you personally need to consume at that moment. Or, how about a stunning geometric biscuit that’s made primarily from crickets? Maybe that’s actually the last thing you want to pop out of your printer.

Food is just the latest area that could be revolutionised by 3D printing – a process known as additive manufacturing. Right now, there are three key areas of interest: printing live tissue to create edible meat that hasn’t come from an animal; printing palatable snacks made from highly nutritious (but slightly repellent) insects; and printing meals tailored to unique dietary requirements. Yes, the future has arrived.

The science of chocolate

Aurora Tjernshaugen is a final year Undergraduate Mechanical Engineering student in the School of Mechanical, Aerospace and Civil Engineering. When it comes to additive manufacturing, her material of choice is chocolate – but it proved to be a pretty tricky ingredient to work with.

If you’ve ever watched The Great British Bake Off, this will come as no surprise. As every keen baker knows, melting chocolate is an art – do it wrong and you’re left with a lumpy mess. This is bad news if you intend to put that chocolate through a printer.

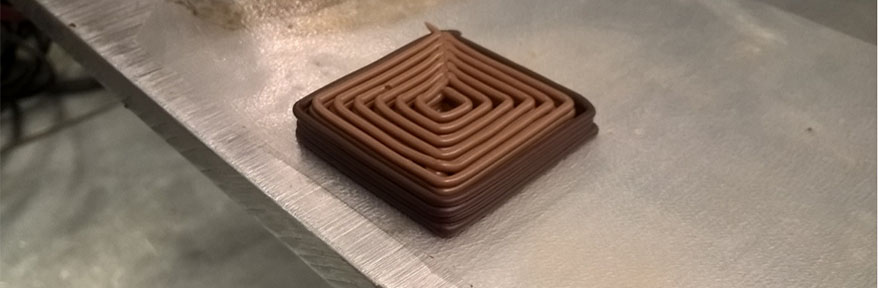

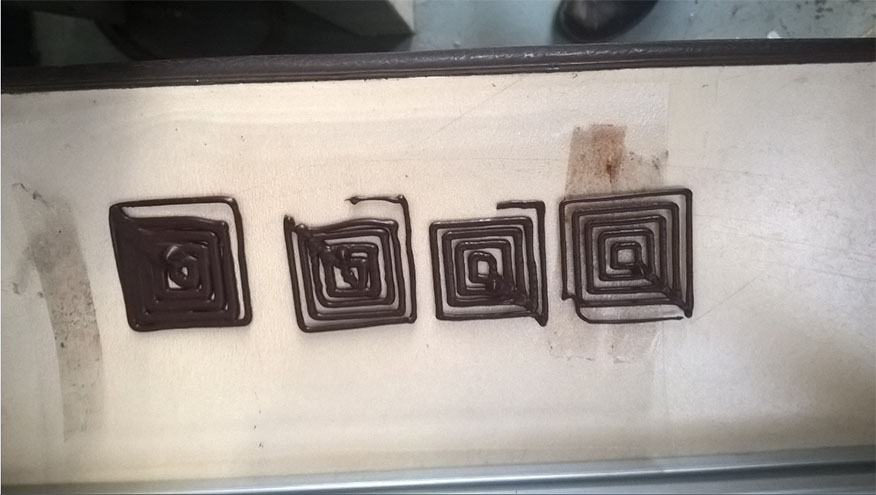

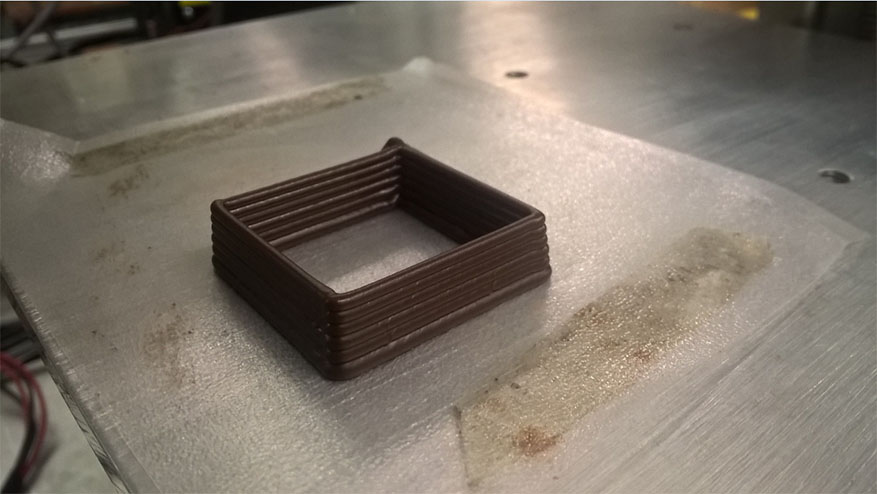

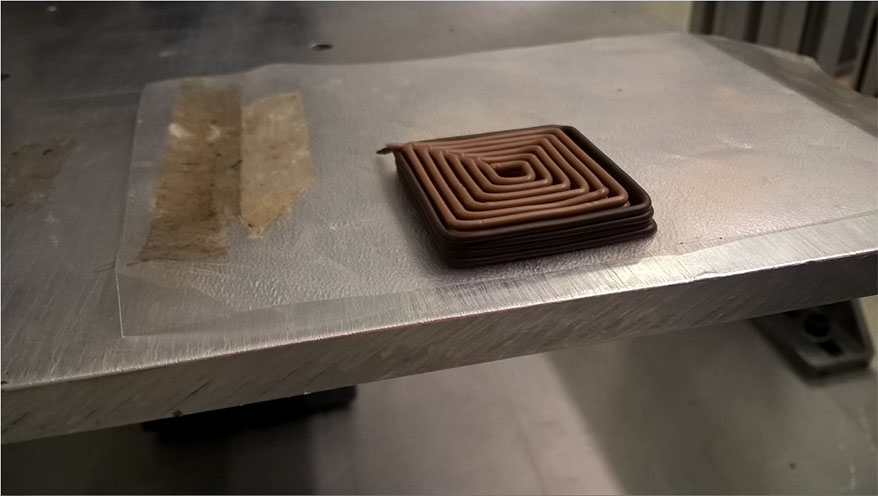

There are six crystallisation phases for chocolate and, as Aurora explains, “only one for it to print correctly” (see photo). Milk chocolate is particularly unstable as it has two fat phases, she notes. But this was just the sort of thing that interests Aurora, as her aim was to investigate the practical complications in the additive manufacturing of food. “Chocolate seemed the most logical material to choose,” she says.

Finding out what can go wrong with food printing is an important step towards making sure it goes right. And once the 3D printing of chocolate – and other food – is ironed out, its applications could be limitless.

Rise of the machines

So, could additive manufacturing one day replace human chefs? Well, 3D chocolate printers could pop up on the high street in the not-too-distant future. Just think; you could order a chocolate in the shape of a cat for your feline-loving friend, or order two bars of chilli chocolate but alter the amount of chilli in each.

Of course, it doesn’t end with chocolate. There’s a huge amount of scope for additive manufacturing right now, as Aurora tells us. “3D printing is something I can see advancing the manufacturing of food in coming years. However, there is still much more research that has to be done in order for this to become common practice.”

A future where you can print out a string of sausages that have little to do with an actual pig is not far off, for example. One possible application of 3D printing is to print out living tissue. On the one hand, this could allow the creation of artificial meat that is formed from layers of manufactured live tissue rather than an animal. This could transform the agricultural industry. And the same technology could be applied to the creation of artificial limbs.

3D printing also has the potential to provide us with beautiful looking snacks that hide a less-than-beautiful main ingredient – insects. There’s a growing school of thought that insects could provide the answer to the world’s hunger problems. They’re nutritious and easy to access, but there’s something a little, now how can we put this scientifically… ‘icky’ about the thought of eating them.

That’s where 3D printing comes in; projects like Insects Au Gratin show how additive manufacturing can be used to turn raw ingredients like crickets into delicious-looking geometric cookies. By making insects more palatable, a greater number of people may be prepared to sample dishes in which they’re included.

If that still doesn’t appeal, how about a meal that’s been tailored to your unique dietary needs? Developments in 3D printing could allow things like the calorie content of dishes to be controlled. If you’re an athlete preparing for an event, this means you can get exactly the number of calories you need to assist you in your training. Or, if you’re pregnant and have been advised by a doctor to reduce your sugar intake due to concerns about gestational diabetes, 3D printing could assist you with this.

We may even come to a time when the Star Trek ‘replicator’ – a device on board the Enterprise that created any meal on demand – is the must-have gadget in every kitchen. And 3D printing engineers aren’t the only researchers to be slaving over a hot stove of scientific innovation.

The Science and Technology Facilities Council (STFC) Food Network+ will launch at the end of June. This interdisciplinary community is working to provide a sustainable, secure supply of safe, nutritious and affordable high-quality food using less land and with reduced inputs – no small task! The network has been set up by The University of Manchester’s Sarah Bridle, a professor of Astrophysics. The Food Network will see her apply her cosmology experience to the agricultural sector, with a focus on reducing the impact of climate change on food.

Words – Hayley Cox